Most Popular Product

|

Automatic Industrial Filter Press

100000 - 10000000 INR/Piece

Product Details:

- Product Type Automatic Industrial Filter Press

- General Use Industrial Solid-Liquid Separation

- Material Mild Steel (MS), Polypropylene Plates

- Type Automatic

- Capacity 5-100 TPD (tons per day)

- Weight (kg) 1200-4500 kg (varies by model)

- Computerized Yes

- Click to View more

X

Automatic Industrial Filter Press Price And Quantity

- 1 Piece

- 100000 - 10000000 INR/Piece

- Up to 80°C

- Up to 7 Bar

- Optional, as per requirement

- ISI/ISO Certified

- Slurry, Effluent, Industrial Wastewater

- Continuous

- Skid Mounted or Onsite Installation

- Semi-Automatic/Automatic Hydraulic Closing

- 470 x 470 mm to 1000 x 1000 mm (as per model)

- Polypropylene

- 20-40 mm

- Automatic End Plate Sealing

- <75 dB

- Automatic Cake Discharge

Automatic Industrial Filter Press Product Specifications

- PLC Based

- No

- 1200-4500 kg (varies by model)

- Blue/Grey

- Automatic

- Mild Steel (MS), Polypropylene Plates

- Industrial Solid-Liquid Separation

- 3-7.5 HP

- Hydraulically Operated, Corrosion Resistant, Robust Structure

- Yes

- 20-200 m

- Yes

- 5-100 TPD (tons per day)

- Automatic Industrial Filter Press

- 415V, 50 Hz

- 4200 x 1250 x 1400 mm (approx., varies by capacity)

- 5-40 m/h

- No

- Variable (as per plate quantity)

- Up to 80°C

- Up to 7 Bar

- Optional, as per requirement

- ISI/ISO Certified

- Slurry, Effluent, Industrial Wastewater

- Continuous

- Skid Mounted or Onsite Installation

- Semi-Automatic/Automatic Hydraulic Closing

- 470 x 470 mm to 1000 x 1000 mm (as per model)

- Polypropylene

- 20-40 mm

- Automatic End Plate Sealing

- <75 dB

- Automatic Cake Discharge

Automatic Industrial Filter Press Trade Information

- 10 Piece Per Week

- 15-30 Days

Product Description

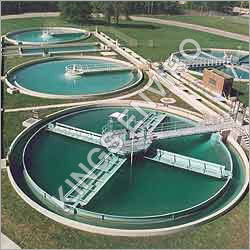

We are the leading supplier and manufacturer of Automatic Industrial Filter Press.

Application:

- Effluent Treatment Plants-Textile, Paper, Leather, Jute Sewages, Industrial & Municipal waste water.

- Ceramics-Clay, Porcelain, Fine Earth, Mark able and Granite.

- Metallurgy-Electroplating & Electro Polishing, Steel Mill Waste. Nickel, Copper, Zinc Lead, Silver etc.

- Pharma Industries-, Syrup, Intermediates and Bulk Drugs.

- Chemical Industries-Basic Chemicals, Organic & Inorganic, Resins, Starch, Enzymes, Pesticides, Activated clay, Phosphoric compounds, Marine Chemicals.

Specification

| Automation Grade | Automatic, Semi-Automatic |

| MOC | MS powder coating |

| Brand | Kings Eva |

| Power | 2-10 HP |

| Service Type | Installation, Repairing |

Automated Hydraulic Operation

The filter press uses an automatic hydraulic closing system, facilitating seamless, hands-free cake discharge and plate sealing. This reduces manual intervention, optimizes process efficiency, and ensures consistent filtration cycles, making it ideal for high-volume industrial operations.

Reliable Construction and Safety

Constructed with mild steel frames and polypropylene plates, the press provides excellent corrosion resistance and structural integrity. Certified to ISI/ISO standards, it guarantees safe, long-term use in harsh industrial conditions, offering peace of mind for operators.

Customizable Installation and Capacity

Whether your plant requires skid-mounted convenience or onsite assembly, this filter press adapts to space limitations and operational needs. With capacities from 5 to 100 tons per day and filter areas up to 200 m, it supports diverse scale requirements and processing flows.

FAQs of Automatic Industrial Filter Press:

Q: How does the automatic filter press manage cake discharge and plate sealing?

A: This filter press features an automatic hydraulic closing system and automatic end plate sealing, resulting in consistent, sealed plate operation and automatic cake discharge. It significantly reduces manual handling and process downtime.Q: What are the main industrial uses for this filter press?

A: It is designed for the solid-liquid separation of slurry, effluent, and industrial wastewater across industries such as chemical, pharmaceuticals, food processing, and mining. Its robust build and continuous operation suit demanding applications.Q: When is skid-mounted installation recommended?

A: Skid-mounted installation is ideal when mobility or rapid deployment is essential, allowing easy setup without extensive onsite construction. Alternatively, onsite installation is chosen for permanent, large-scale operations where space and infrastructure permit.Q: Where can the filter press be installed within a facility?

A: The system can be installed in process lines handling industrial fluids, typically situated near sludge storage, wastewater treatment areas, or batch processing units. Its compact dimensions and customizable capacity enable flexible placement.Q: What is the process for slurry feeding and separation?

A: Slurry is introduced at up to 7 Bar pressure (with optional feeding pump). The hydraulic system closes the plates, and filtration proceeds, forming cakes of 20-40 mm thickness, which are automatically discharged. The PLC system monitors and controls each cycle for optimized separation.Q: What are the benefits of using this automatic filter press?

A: Benefits include reduced labor, reliable continuous operation, robust corrosion-resistant construction, low noise (<75 dB), and high filtration efficiency. Its computerized PLC controls and certified design enhance safety and operational consistency.Q: Can temperature-sensitive slurries be processed with this filter press?

A: Yes, the filter press is engineered for temperature resistance up to 80C, making it suitable for applications involving moderately heated slurries and liquids.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Filter Press' category

|

KINGS INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |